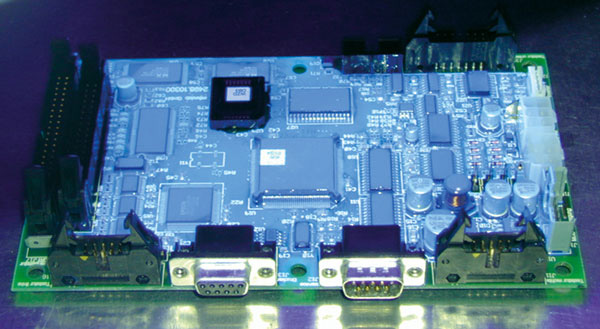

Our core competence is the protection of electronic components and boards via conformal coating.

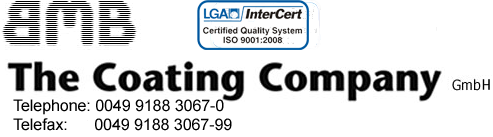

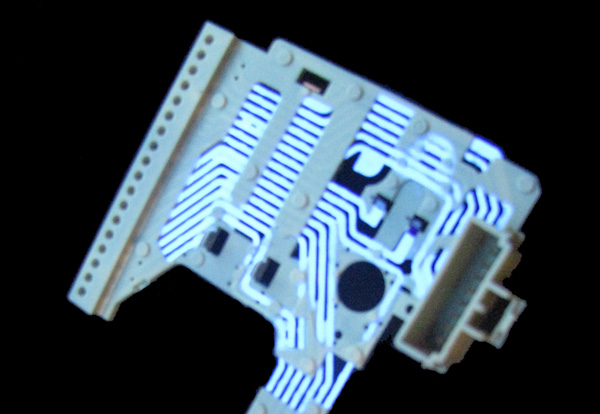

Coating of electronic components: Coated electronic boards checked under UV-Light.

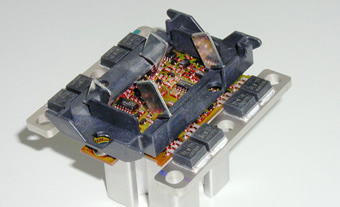

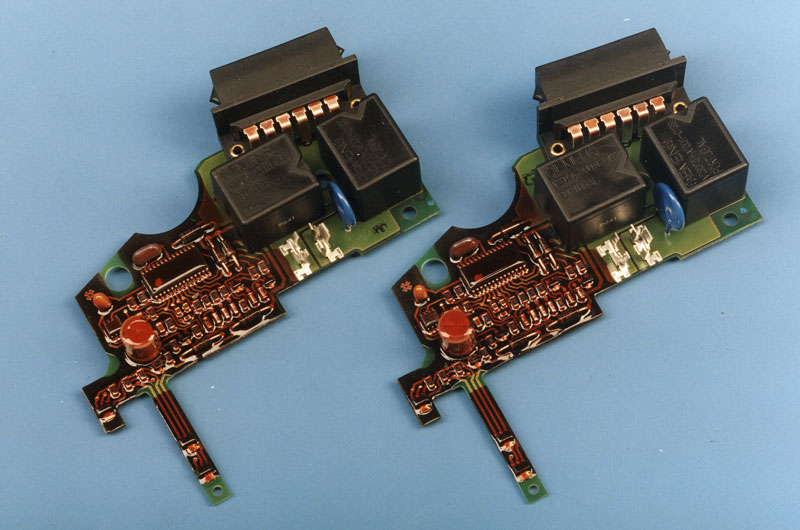

The picture shows a typical conformal coating application.

WHY CONFORMAL COATING?

The elevated integration level of electronic components and smaller and smaller geometries of PCBs and components raises new problems relating to durability and reliable function under harsh climatic conditions.

The reliability of any component is basically not only determined by material, design and fabrication but also in an important way by the operating condition.

Electronic components are normally applied in the engine compartment, outdoor, in car parks and dwellings, in tools and domestic appliances etc. which means everywhere where unfavourable environmental conditions can directly influence.

CORROSION RESISTANT COATINGS

Corrosion resistant coatings are important: dirt accumulations, elevated air humidity and dew, corrosive gases, fungus infestations, high operating temperatures as well as mechanical influences (e.g. vibrations, mechanical shock) are only a few examples of mechanisms that can cause disturbances and consequently a complete failure of the electronic component.

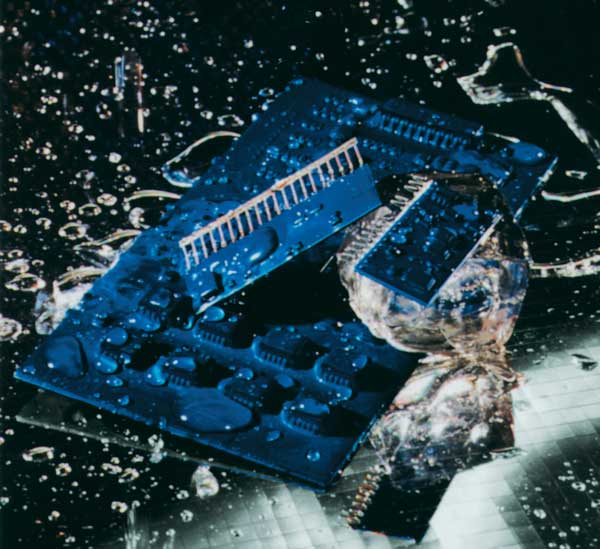

- Humidity, protection against condensation and short circuits

- Vibrations, e.g. with boards in washing machines

- Corrosive media, e.g. salt fogs (wind turbines)

- UV resistance, moulds (on LED displays)

- Cycles of temperature change, e.g. in heating thermostats

The reliability is a decisive quality criterion because a PCB can only work within certain limits.

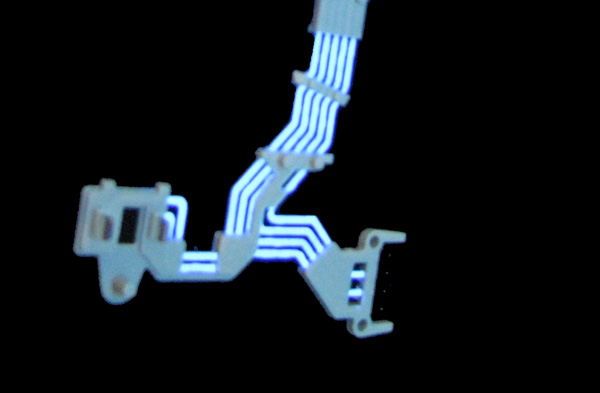

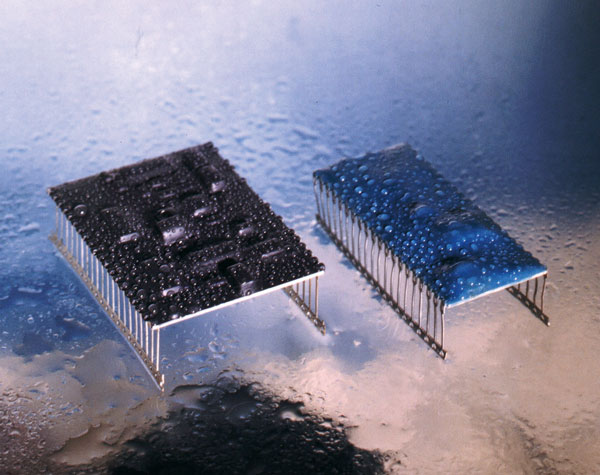

WATERPROOF COATINGS

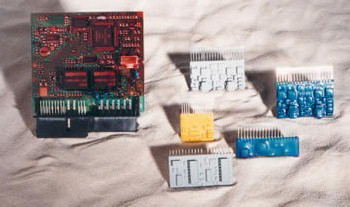

Boards with waterproof coatings:

To guarantee a reliable function, waterproof coatings of the boards are required.

To guarantee this, we develop processes, manufacture complete coating equipments and coating machines that make it possible to process proven materials in an economic way.

In own service centres we offer conformal coating of electronic components as a service.

At the same time we develop our methods and machines further under production conditions in our service centres.

WE OFFER DIEFFERENT COATING METHODS AS A SERVICE

- Dip coating

- Select Flood coating

- Spray coating

- Potting

Each coating method has its own advantages and disadvantages.

We can offer you every method in the area of machine engineering in order to design an individual coating machine but also as a service in our company.